#Transports: Automotive/ Aerospace

Lighter Seatback Thanks to Carbon Fiber Structure

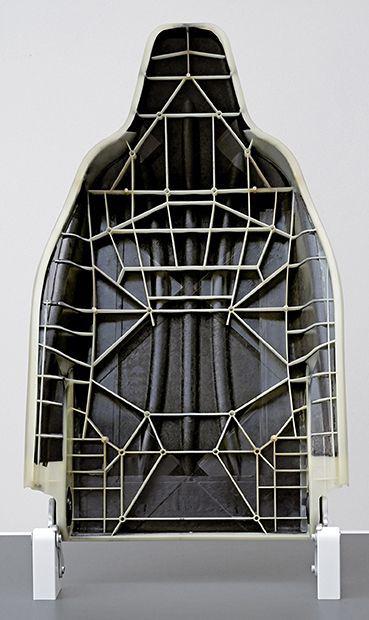

Working together with several project partners, Johnson Controls developed a new seatback structure for motor vehicles

Four different components are used to manufacture the part: steel, glass fiber-reinforced plastic (GFP), a nonwoven carbon fiber mat and thermoplastic tape containing continuous carbon fiber.

The nonwoven carbon fiber mat is first thermoformed and provides the basic shape of the seatback. Carbon fiber-containing tapes are then used to increase the strength in specific regions of the seatback. The glass fiber-reinforced thermoplastic rib structure is then created by means of injection molding. This rib structure also has the attachment points for foam, seat cover and safety elements. Specially coated steel adapter pieces placed in the mold prior to injection form a positive connection and hold the two seat adjusters. The seat adjustment mechanisms are attached to the seatback in a separate step via laser welding.

Crash tests simulating a rear-end collision have already been conducted with the newly developed seatback. For these, the seatback prototype was mounted to a conventional seat base. This sample seat met the strength requirements for seats with a metal structure produced in high volume.

Based on the current status of the project, the newly developed seatback is over 40 lighter than a conventional metal seatback. Moreover, function integration reduces the assembly steps during production. The manufacturing process can be designed for volumes of about 200,000 units per production line and year. In the future, it should be possible to coat the visible surfaces of the seatback during the production process in order to provide attractive design and differentiation possibilities in the vehicle's interior. According to current plans, customers should have access to the results of the project as of the 2019 model year.