#Transports: Automotive/ Aerospace

"Super Engine" Could Yield 50% Fuel-Efficiency Gains

The U.S. Department of Energy's Argonne National Laboratory is working with Achates Power and Delphi Automotive to develop an engine that could yield efficiency gains of up to 50% over a comparable conventional engine.

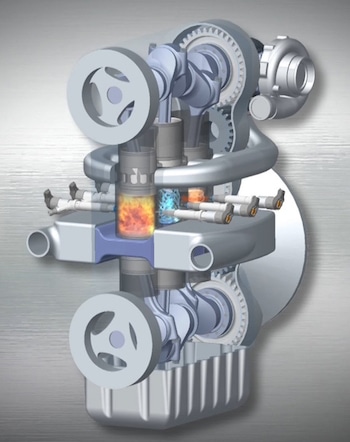

The new engine combines two promising technologies—gasoline compression ignition and opposed pistons—to create a "super engine" that could fundamentally change the way internal combustion engines work in the light-duty transportation market.

"Conventional spark-ignited engines have improved so dramatically over the past few decades that there is little room to make big efficiency gains," says Steve Ciatti, mechanical engineer at Argonne. "You need a game changer to get into large double-digit efficiency gains, and we believe this engine is capable of doing that."

The new engine melds the best characteristics of gasoline and compression ignition engines with an innovative piston architecture refined by Achates Power that sets two pistons moving in opposition in one cylinder. As the crowns of the pistons slide toward each other, they compress a mixture of air and gasoline to such extreme pressures that the mixture auto-ignites without the need for spark plugs.As the pistons reverse course and slide to opposite ends of the cylinder, ports machined into the cylinder allow exhaust gases to escape while fresh air is taken in, then the pistons move together again to compress and ignite in a two-stroke cycle. The design eliminates cylinder heads—which are a major cause of heat loss and inefficiency in conventional engines—and allows the engine to run with diesel-like efficiency and power, while maintaining gasoline's emissions benefits.

An analysis by Achates Power indicates the new engine will yield fuel efficiency gains of more than 50% compared with a downsized, turbo-charged, direct-injection gasoline engine, while reducing the overall cost of the powertrain system.

A key to the success of the project will be the modeling and simulation of the complex fluid dynamics and combustion inside the engine, which will be conducted through Argonne's Virtual Engine Research Institute and Fuels Initiative (VERIFI). By using high-performance computing to model and predict the movement of fuel and air in the cylinders, the VERIFI team will be able to optimize the design of the engine and fuel injectors using computing rather than prototyping, which will enable accelerated development.

"Modeling and simulation have become ever more important to engine designers in recent years," says Sibendu Som, Argonne's computational lead for the project. "Using VERIFI to optimize combustion technologies for industry has significantly shortened development times and helped lead to more efficient engines."

Shorter development time through computational modeling and efficiency gains developed through experimental research will be critical to the creation of an engine that can be widely adopted commercially. Many engines have been proposed over the years that show benefits over conventional spark-ignited gasoline engines, but the efficiency gains have not been dramatic enough to convince auto manufacturers to retool production lines and car designs to incorporate the new approaches.